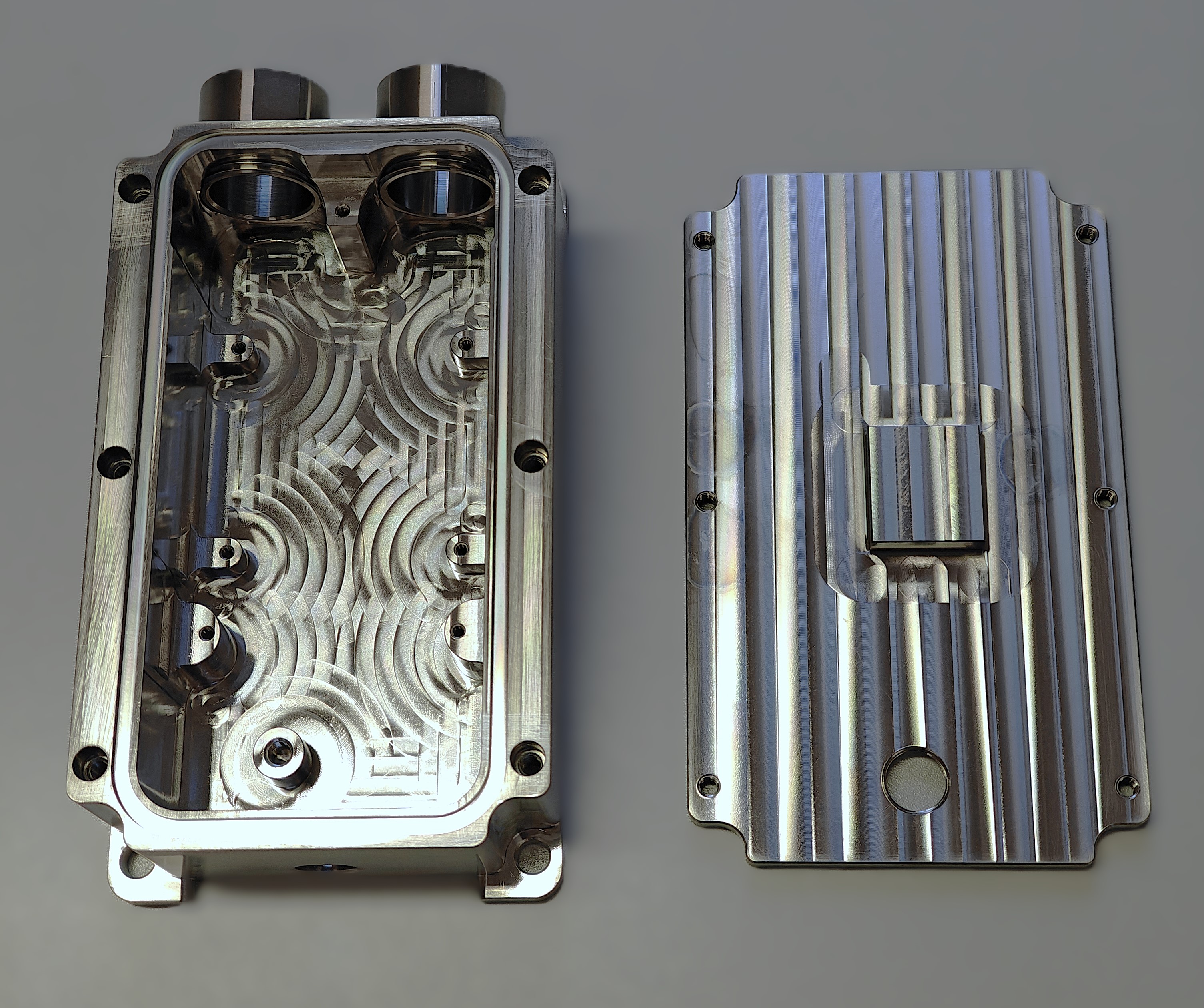

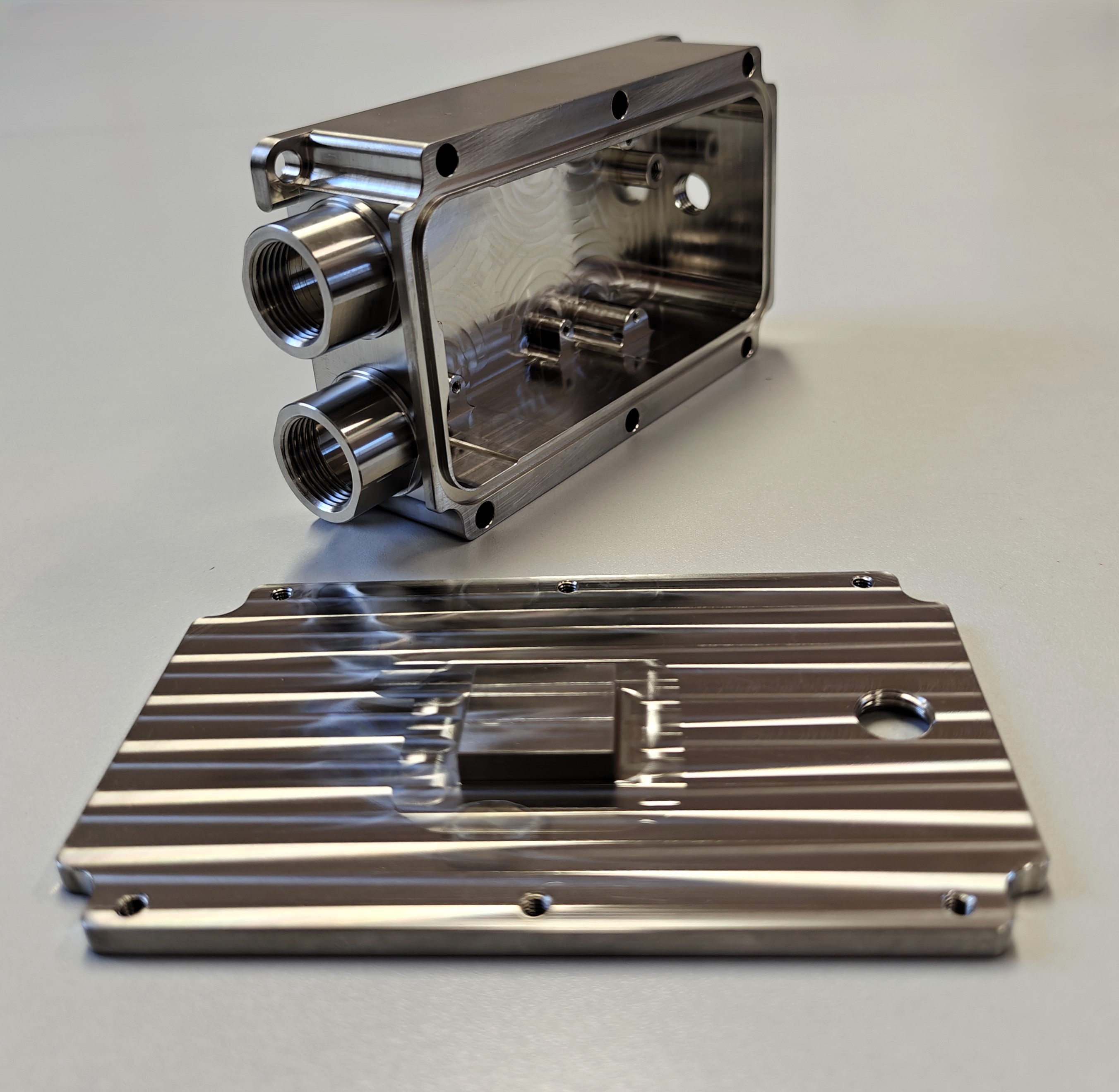

We successfully completed a milling project for Dewesoft, a leading manufacturer of advanced measurement equipment. The task involved machining housings from stainless steel 1.4404 (AISI 316L) — a technically demanding material that requires deep expertise, experience, and top-quality equipment.

Why 1.4404?

Stainless steel 1.4404 is highly resistant to corrosion and is commonly used in environments with the strictest hygiene standards — such as in the pharmaceutical industry, where we have many years of experience. This know-how enabled us to adapt quickly and efficiently to the project’s requirements.

The customer expected:

- High dimensional accuracy,

- Fine, visually appealing surface finishing of the visible outer areas, and

- Fast production turnaround and responsive support throughout all stages of the project.

By using modern CNC machinery, carefully selected cutting tools, and optimized machining parameters, we were able to meet all requirements without compromise. The project was completed within the agreed timeframe, with consistent communication and technical support provided throughout.

Building trust through local partnerships

We firmly believe that cooperation between local companies is key to long-term growth, greater flexibility, and shared competitive advantage. Collaborating with domestic high-tech companies such as Dewesoft not only results in successfully completed projects but also strengthens trust, knowledge, and the development of the entire region.

Looking for a reliable partner for precision metal machining?

Share your project with us — we’ll be happy to help you find the optimal solution.